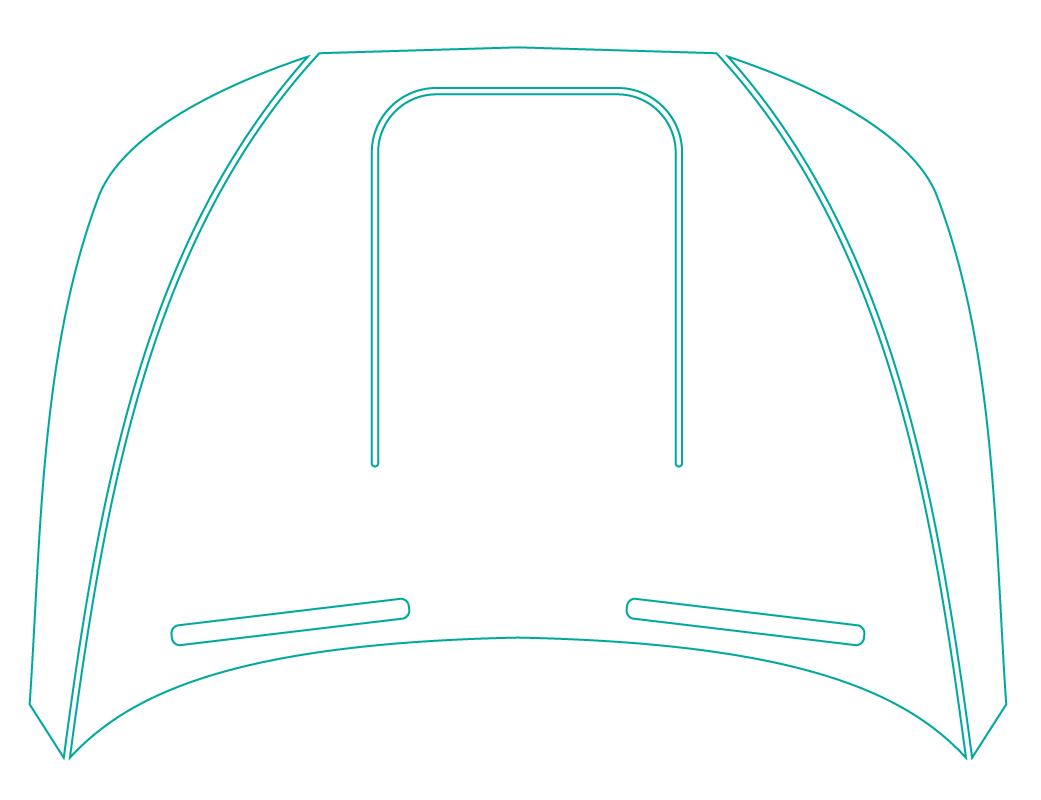

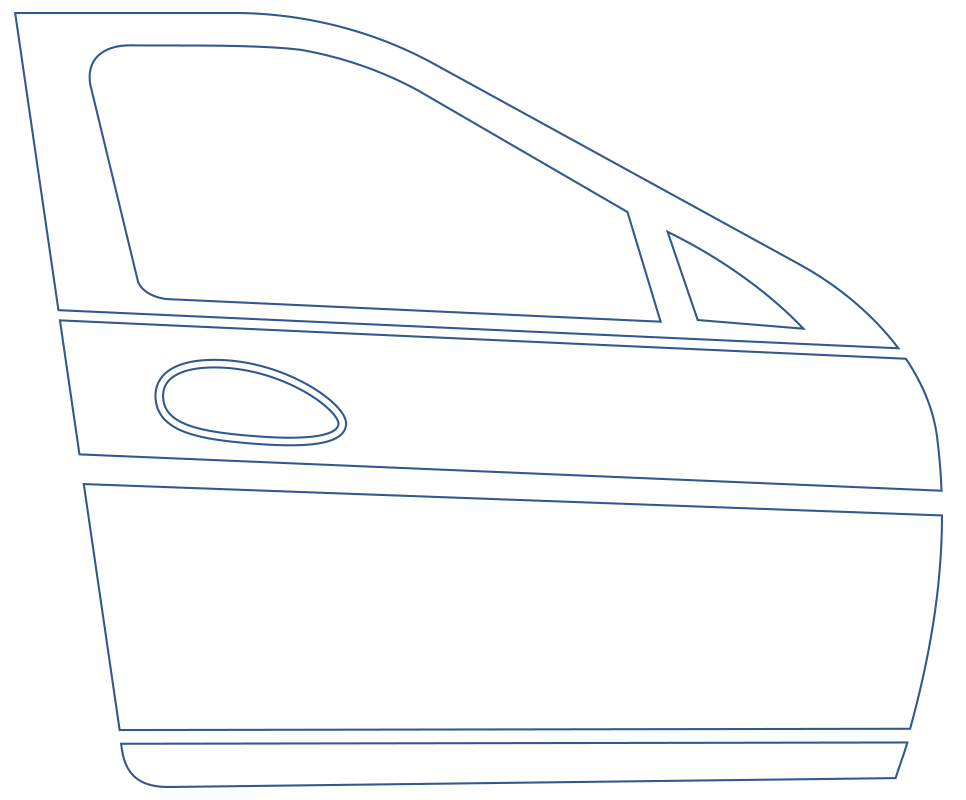

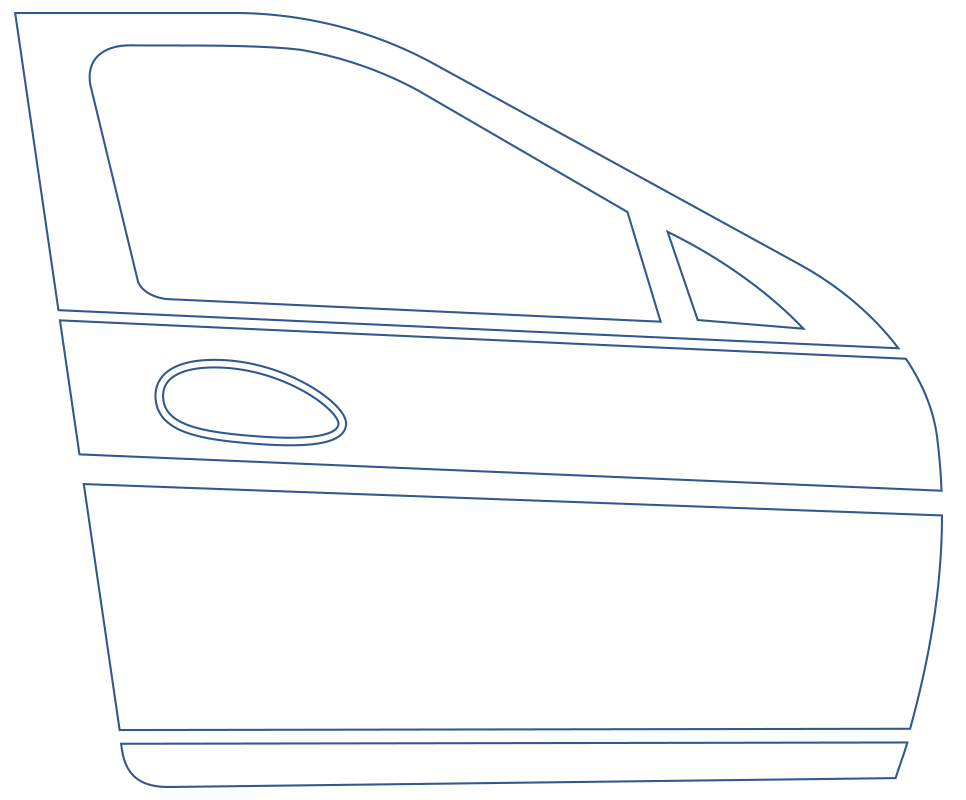

We are proficient in managing the entire process from start to finish.

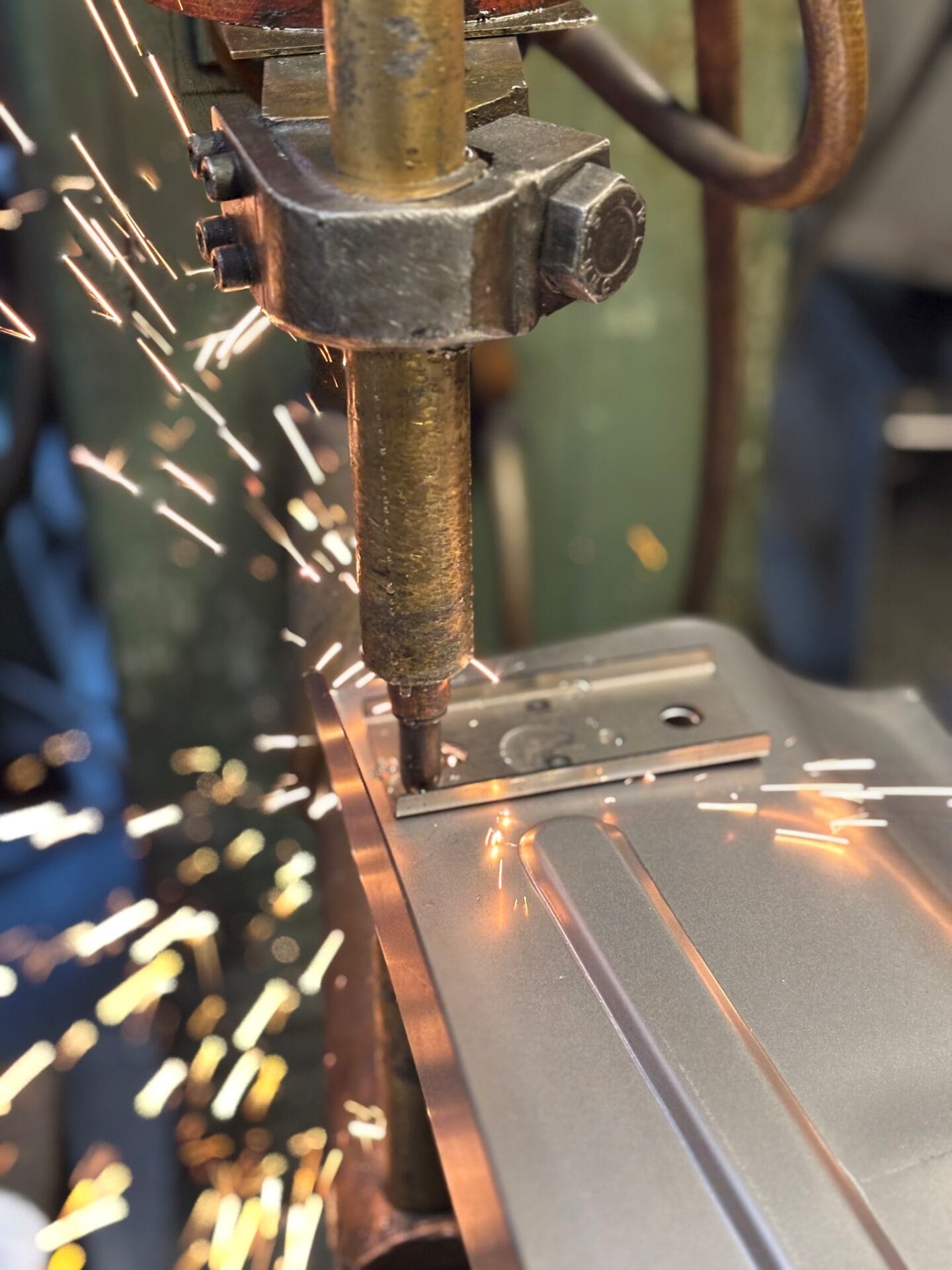

The plant operates 10 presses from 20 to 600 tonne, which offer the capacity for small (hand tool strip) medium (pick & place) through to full high volume production working with materials including steel stainless steel and aluminium.

Our expertise include:

With this extensive range of capabilities, we offer our customers complete flexibility, ensuring the most efficient and cost-effective press solution to meet their specific production needs.

| Press | Bed Area | (mm) |

|---|---|---|

| Rovetta | 600 ton | 3400 x 2100 |

| Reha | 600 ton | 3650 x 2130 |

| BC | 450 ton | 3200 x 2000 |

| HEC | 400 ton | 2140 x 1670 |

| Rhodes1 | 300 ton | 2000 x 1250 |

| Rhodes2 | 300 ton | 2750 x 1350 |

| Fonyu | 250 ton | 2600 x 950 |

| Fonyu | 110 ton | 730 x 680 |

| Hme | 20 ton | 550 x 400 |

| Brake press | 2.5m x 75 ton | 730 x 680 |

| Guillotine | 2.9m x 6mm max cut |

Plus -Spot welders x2 and Mig welder

Our skilled engineers excel in designing complex shapes, guiding each project from initial concept to finish part with precision and care.

Our Prototyping service provides rapid and accurate development of metal components before full-scale production. By utilising precision tooling, prototypes can be created to test design feasibility, functionality, and manufacturability. This process helps identify potential design improvements, reduce production risks, and ensure compliance with quality standards. By offering quick turnaround times and cost-effective solutions our prototyping services enables manufacturers to refine their products efficiently before committing to mass production.

We provide milling, boring, and drilling modification’s and adjustments to tooling during the protype and tooling try-out process. This in-house capability ensures that any necessary adjustments can be made promptly, reducing downtime and maintaining the continuity of production.

Specialising in low and medium volume production, we deliver consistent quality in both regular and occasional batches. Our production processes are to optimised to handle varying order sizes efficiently, ensuring that every product meets our stringent quality standards

We work with a variety of materials, including steel, stainless steel, aluminium in various hardness levels. Our extensive material knowledge allows us to select the best materials for each application, ensuring optimal performance and longevity of the final product.

With specialised equipment and extensive experience, we excel in deep drawing techniques, ensuring high-quality results for intricate components. Our deep draw presswork capability allows us to create parts with greater depth and detail, which is essential for industries requiring precise and durable components.

Our diverse range of presses and skilled setters enable us to offer quick turnaround times, perfect for just-in-time requirements. We understand the importance of agility of manufacturing, and our flexible production processes are designed to adapt to varying production volumes and time tables.